Clothing in Palestine.. Imported Products Damage Local Ones!

Most of the clothes Palestinian citizens purchase from the markets are imported. Statistical reports show that Palestine’s clothing imports in 2013 reached 7,058 million US Dollars.

Ramallah- Palestine Economy Portal | Ansar Tomizy- Clothing ranks fifth in the expenditures of the Palestinian citizen. According to the 2011 reports of the Central Bureau of Statistics, the average of expenditures on clothing per person has reached 10.4 JDs per month, divided as follows: 12.2 JDs in the West Bank, and 7.5 JDs in Gaza Strip. However, the Palestinian market which includes about 1966 clothing and textile factories receive only a tiny share of this demand.

Free Trade System

A clothing merchant does not need a permit for importing products; all they need is a “card of foreign Trade Dealing,” which enables its holder to import clothes from abroad. Observers believe that the free trade system has affected the local clothing industry in a negative way, as several factories had to shut down, and turn into production lines for the Israeli factories.

For example, wholesaler Mohammed Hassan says that he travels to China and Turkey to import clothes. He then sells them to local merchants, which returns feasible profits to him.

Khalid Aarja, President of Palestine Textile Union and owner of a textile factory, says that importing clothes has harmed the local clothing industry, especially as the high operating costs increase the costs of the local products. The costs of water, which is important for dyeing, as well as the costs of electricity and fuel used to operate the machines are very high, while governmental support is absent from the scene.

Aarja pointed out that several Palestinian factories work as production lines for Israeli factories, where they assemble items of clothing for a fee. Aarja also believes that the customs tax on imported Chinese clothes, which is 35%, is not viable, as many importers manipulate the amounts of imported clothes and claim incorrect numbers to pay less customs. The harm has also reached the raw materials sector, as Palestinian factories now import raw materials from China and Turkey instead of the local market.

Aarja says that one kilo of local fabric costs 30 NIS, while Turkey’s imported fabric costs 27 NIS per kilo; thus causing merchants to purchase Turkish fabric. He called on the government to support and encourage local clothing industry, and contribute in lowering its costs.

A Decline in the Value Added

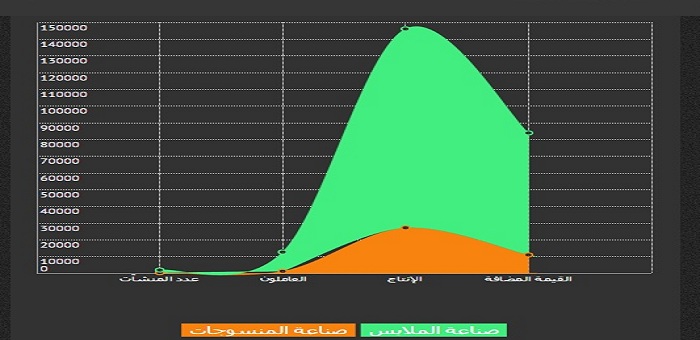

Statistics that Palestine Economy Portal has received from the Ministry of Economy show that the number of clothing and textile establishments reached 1966 in 2013, which constituted 12% of the total number of industrial establishments in the West Bank and Gaza Strip. In the same year, clothing and textile industry employed around 12,735 workers, which constituted about 16% of the total workforce in the industrial section. In 2013, clothing and textile industry contributed in 5.1% of the industrial value added, which has declined from the 2012 ratio of 6.3%.

A graph showing the status of the clothing and textile industry in 2013

Radical Solutions for Advancement

In an attempt to improve the sloping curve of the local clothing and textile industry, economic expert Samir Abdallah said that the solution lies in producing goods with a high value added, at high quality and prices; and moving away from competing the cheap imported products. That is, producing clothes that are capable of competing the foreign market and gaining its trust, with the presence of good distribution and marketing.

Abdallah explained that the high operating costs of the local factories do not allow them to compete the products imported from China and other Asian countries, not even some of the Arab countries with low operating costs and cheap workforce. Therefore, we must raise the quality and price of the local product, and move from the local market to global and elite one, in order to save the local clothing industry and upgrade it.

Abdallah said that, for example, the Palestinian factories shouldn’t compete on producing suits that cost $100, but rather produce suits that cost $1000 to be able to export them, or sell them to high-income citizens.

Owners of local factories can also gain the trust of the international brands companies, which would then allow them to produce clothes with the labels of these brands.